RHIM’s Pedra Preta magnesite mine, Brumado, Bahia, which has been active since 1943, supplies feedstock raw material for dead burned and caustic calcined magnesia grades for domestic and export markets.

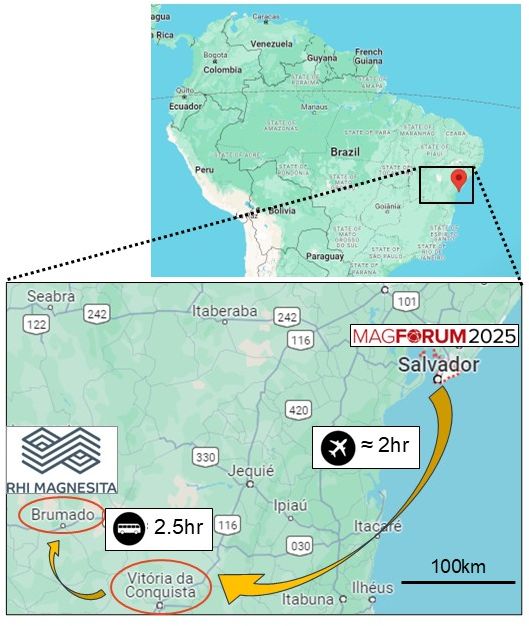

IMFORMED is delighted to be able to offer delegates an exclusive opportunity to visit the operations of RHI Magnesita at Brumado, Bahia, in the heart of Brazil’s famous magnesite producing region.

The Field Trip takes place the day after the conference, ie. Thursday 22 May (Welcome Reception Monday evening, 19 May; conference on Tuesday and Wednesday 20 & 21 May).

SUBJECT TO AVAILABILITY

PLEASE NOTE: There are very limited places: to attend the Field Trip you must register for the conference and tick box Field Trip attendance; there is an additional fee (US$300 | £240 | €285) for the Field Trip which includes all transport, meals and refreshments; please register online here or contact Maria maria@imformed.com.

Provisional itinerary*

05:45 Meet Hotel Lobby for imminent departure

06:00 Depart Tivoli Hotel for Salvador Airport

08:15 Flight from Salvador to Vitória da Conquista (1hr 20min)

10:15 Bus from Vitória da Conquista Airport to Condado, Brumado

12:45 Briefing & Lunch (Safety rules; PPE)

13:35 Transfer from Condado to Catiboaba plant

13:45 Catiboaba plant tour

14:15 Transfer from Catiboaba to Pedra Preta mines & plant

14:35 Pedra Preta plant tour (2 Mines, Geology Shed and Rotary Kiln)

16:15 Pedra Preta mine blast

16:45 Social Project (Community Garden); Coffee & Closing

17:30 Bus transfer from Condado to Vitória da Conquista Airport

21:00 Flight from Vitória da Conquista to Salvador Airport

22:25 Arrive Salvador Airport; transfer by bus to Tivoli Hotel

00:00 Arrive Tivoli Hotel

Please wear clothing and footwear as befits a working industrial site visit.

*subject to change

RHIM’s Catiboaba plant, Brumado, Bahia.

Overview

RHI Magnesita (RHIM) is a global leader in magnesia and refractory products. In Brazil, it operates in several states, including the unit located in Brumado, Bahia, where magnesite is extracted from the Pomba and Pedra Preta mines for the production of dead burned (sintered) and caustic calcined magnesia.

A large part of the production of natural magnesite derivatives is consumed by the company itself in refractory manufacturing, while the remainder is for export.

The Brumado unit began operations in 1943 with the opening of the Pedra Preta mine. Four years later, the first vertical sintering furnace was installed in the same location.

The new rotary kiln installed at Brumado as in May 2024; currently in ramp-up phase.

In the 1970s, the HW1 furnace was installed and later, with the expansion of activities and the opening of the Pomba mine, the HW2 furnace.

In 2003, the Catiboaba industrial plant was expanded with the operation of the HW3 furnace. The HW4 Furnace began operations in 2012, together with the expansion of the Ore Treatment Unit – UTM.

In 2020, RHIM announced a €30m investment for the construction of a new 140,000 tpa rotary kiln to accelerate vertical integration in Brumado – the Hexa Brumado Project.

The installation of the new rotary kiln at the Pedra Preta Unit will enable production of sintered magnesia with greater efficiency, extending the life of the mine, and in line with the best sustainability practices, permitting development of a new portfolio of raw materials.

By 2024, the Brumado project was completed and is currently in ramp-up phase.

Raw material (magnesia) production at Brumado was 345,000 tonnes in 2023.

Total production capacity of finished products at Brumado is 600,000 tpa.

Source: RHI Magnesita